3-D Organ printing

What is Organ Printing?

It’s hard to imagine, isn’t it, that human organs might one day be ‘printed’ for medical use. But it could become a reality if a number of recent advancements in the medical tech sphere are anything to go by.

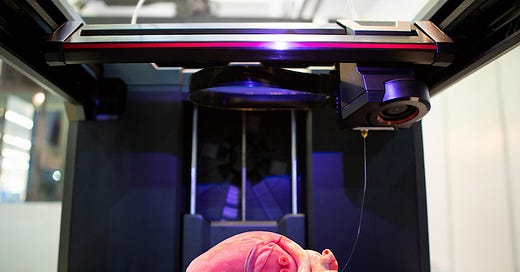

A printable organ is an artificially constructed device designed for organ replacement, produced using 3D printing techniques. The ultimate goal of organ printing is to create organs that can fully integrate into the human body as if they had been there all along. Bioprinting is a method that enables cellular made from bio-inks loaded with stem cells. Layer by layer, the biomaterial is deposited to create skin, tissue or even an organ. Bioprinting projects are growing, and each new project is one step closer to being a fully functional and viable solution. Laboratories and research centres are bioprinting human livers, kidneys and hearts. The objective is to make them suitable for transplantation and sustainable long-term solutions. There is still progress to be made!

Why Organ Printing?

“The motivation for this research was the shortage of donor organs for transplantation so we are driven to realise this technology. However, it will take many years to achieve functioning organs “

Successful organ printing has the potential to impact several industries. These include organ transplants, pharmaceutical research, and the training of physicians and surgeons.

3D bioprinting technologies could offer hope to people who currently rely on donor organs. Artificial organs printed using bio-ink made from a patient’s own cells could eliminate the need for a transplant altogether, removing the need for organ donors and reducing the risk of tissue rejection.

Printed organs have been used to model structure and injury to better understand the anatomy and discuss a treatment regime with patients. These model organs provide advancement for improving surgical techniques, training inexperienced surgeons, and moving towards patient-specific treatments. Also, organ printing has been used as a transformative tool for in vitro testing. The printed organ can be utilized in discovery and dosage research upon drug-release factors.

Organ printing technology can also be combined with microfluidic technology to develop organ-on-chips. These organs-on-chips have the potential to be used for disease models, aiding in drug discovery, and performing high-throughput assays.

The Origin :

The field of organ printing stemmed from research in the area of stereolithography, the basis for the practice of 3D printing that was invented in 1984. In this early era of 3D printing, it was not possible to create lasting objects because the materials that were being used were not very sturdy. Therefore, in the early days, 3D printing was simply used as a way to model potential end products that would eventually be made from different materials under more traditional techniques

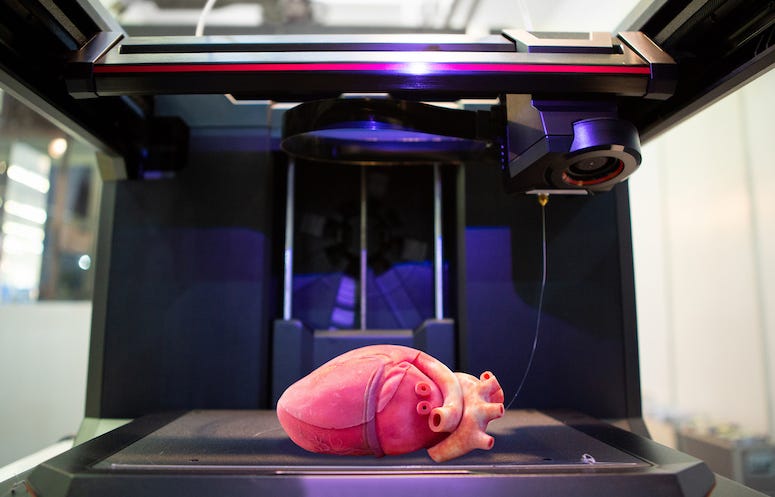

Over the last ten years, further research has been put forth into producing other organs, such as the liver and heart valves, and tissues, such as a blood-borne network, via 3D printing. In 2019, scientists in Israel made a major breakthrough when they were able to print a rabbit-sized heart with a network of blood vessels that were capable of contracting like natural blood vessels. The printed heart had the correct anatomical structure and function compared to real hearts. This breakthrough represented a real possibility of printing fully functioning human organs. In fact, scientists at the Warsaw Foundation for Research and Development of Science in Poland have been working on creating a fully artificial pancreas using bioprinting technology. As of today, these scientists have been able to develop a functioning prototype.

How an Organ Is printed:

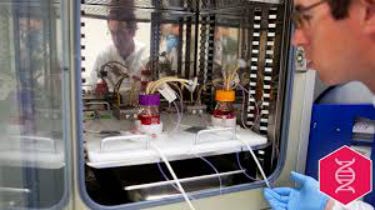

In the case of organ printing, the material being used by the printer is a biocompatible plastic. The biocompatible plastic forms a scaffold that acts as the skeleton for the organ that is being printed. As the plastic is being laid down, it is also seeded with human cells from the patient the organ is being printed for. After printing, the organ is transferred to an incubation chamber to give the cells time to grow. After a couple of days they begin to communicate and form interconnected networks. After a sufficient amount of time, the organ is implanted into the patient.

Challenges:

The challenges faced in the organ printing field extends beyond the research and development of techniques to solve the issues of multivascularization and difficult geometries. Before organ printing can become widely available, a source for sustainable cell sources must be found and large-scale manufacturing processes need to be developed. Additional challenges include designing clinical trials to test the long-term viability and biocompatibility of synthetic organs. It is still lacking significant strides in order to produce complex 3D biomimetic tissue constructs. While many developments have been made in the field of organ printing more research must be conducted.

What Organs Are Printed:

Currently, the only organ that was 3D bio-printed and successfully transplanted into a human is a bladder. The bladder was formed from the hosts of bladder tissue. Researchers have proposed that a potential positive impact of 3D printed organs is the ability to customize organs for the recipient. Developments enabling an organ recipient’s host cells to be used to synthesize organs decreases the risk of organ rejection.

A 3D printed kidney is one of the most difficult. That’s because of the complexity of the organ’s structure, which is necessary for its function. The most promising of 3D printed organs for transplant is the heart. As organs go, the heart is actually one of the easiest to recreate because it doesn’t employ any complex biochemical reactions. Rather, its primary function is to act as a pump.

Using “nanokicking” method, the researchers were able to turn stem cells taken from human donors into 3D bone grafts. The goal is to help those who have suffered landmine related injuries.

Organovo, a San Diego-based bioprinting company, has already demonstrated that it can 3D print human liver tissue patches, implant them into mice and be functionally beneficial. Until liver transplants begin, Organovo is also using their bio-printed liver patches for preclinical testing and drug discovery research. Using multi-cellular 3D human tissues that mimic a real liver, they can better assess the effects of certain drugs and compounds without risking lives.

This is so far only a proof of concept. Transplants for humans require a lot more work to be done to ensure safety and efficacy. . This is a growing field and much research is still being conducted. Till then “Donate Organs, Save Lives!“

An Article By: Biogen Team

DISCLAIMER

Shaastra TechShots’ publications contain information, opinions and data that Shaastra TechShots considers to be accurate based on the date of their creation and verified sources available at that time. It does not constitute either a personalized opinion or a general opinion of Shaastra or IIT Madras. The information provided comes from the best sources, however, Shaastra TechShots cannot be held responsible for any errors or omissions that may emerge.